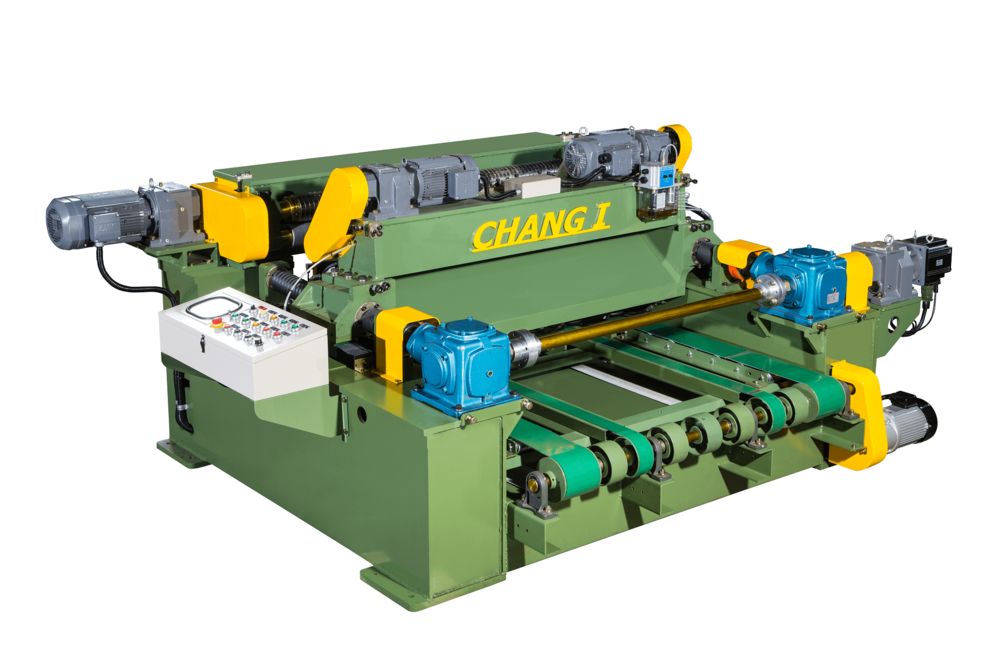

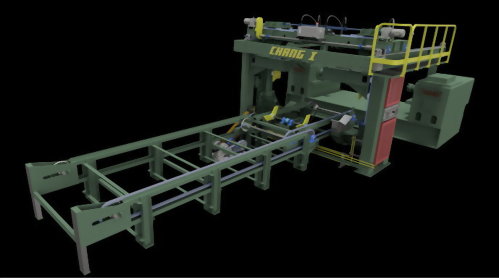

Veneer Spindless Lathe

Automatic veneer peeling machine is widely used in veneer production line for its important function. The device is fixed by double-rollers and adopts advanced AC Servomotor system with PLC controlled , it calculate the current diameter of the wood log and the rotational speed of the friction roller.

This Veneer Lathe CI-VSL Series for log is

a spindle-less log peeling lathe machine configured with PLC controller and

requiring one operator, it’s easy for anyone to learn at short time.

Using touch screen makes the operator easy

working and setting. Also, it saves cost and increase production efficiency.

The AC Servo motor of feeding carriage

system is make in Taiwan and can generate a smooth operation when the machine

works in low speed.

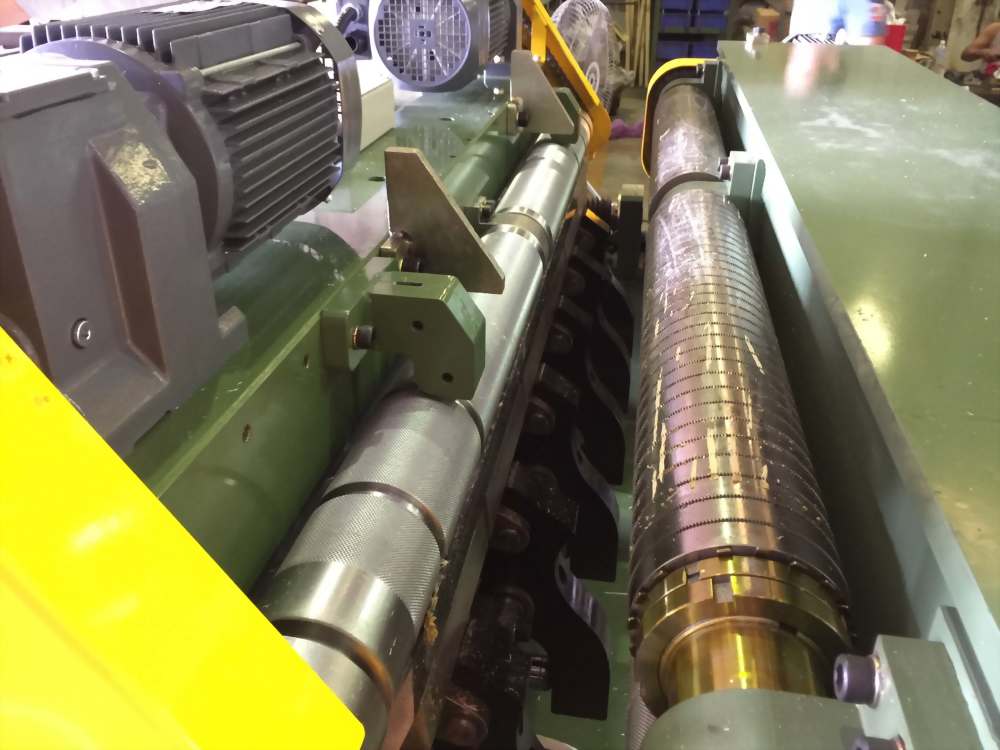

The touch roller has two kind of type, one

of using high strength roller chrome treatment has friction resistance;

another of using spike roller keep peeler quality, especially for peeling

eucalyptus, birch and other hardwood.

High Speed knife carriage long service life and can enable to the veneer to have consistent thickness

Specification:

|

Model: |

CI-VSL1400-SD |

CI-VSL2700-KR |

|

Maximum Length of out |

1400mm |

2700mm |

|

Knife Length |

1450mm |

2750mm |

|

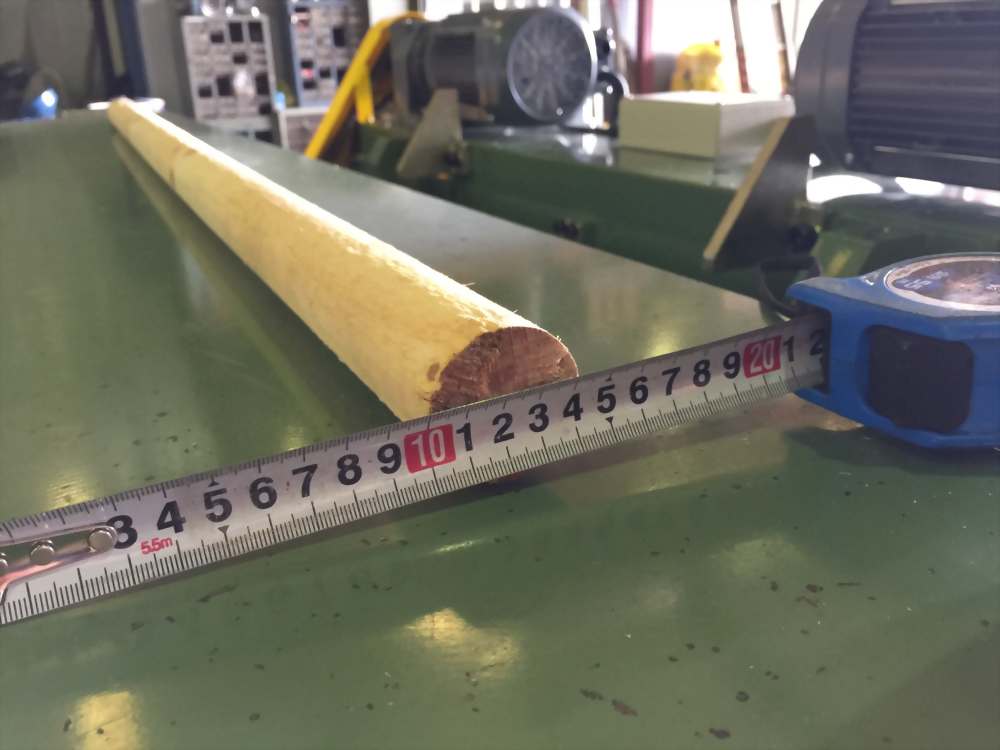

Rated diameter of rotary cut (max) |

Ø 300 |

Ø 380 |

|

Available working thickness |

1.0mm~4.0mm |

0.5mm~3.2mm |

|

Change of veneer thickness |

Setting by H.M.I |

Setting by H.M.I |

|

Diameter of remainder wood |

<35mm |

<60mm |

|

Rotary cut speed |

15-45M/min Auto Change |

15-34M/min Auto Change |

|

Double roller motor |

5.5KW (By Inverter) |

5.5KW (By Inverter) |

|

Single roller motor |

5KW x2 (By Inverter) |

5KW x2 (By Inverter) |

|

Feed motor |

7.5KW |

11KW |

|

Install knife by oil hydraulic cylinder |

YES |

YES |

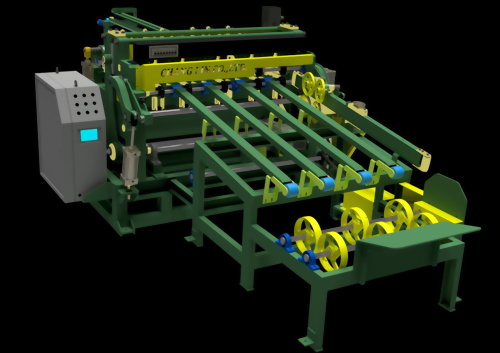

Feature:

A. Logs of various qualities including hard logs and poor grades having natural

defects such as splits, soft core and rotten spots can be peeled to veneer sheets

successfully down to a small core diameter without spin-out.

B. Veneer sheet can be peeled with an accurately controlled thickness.

C. Drying efficiency can be improved and the warping by drying reduced.

D. Power consumption for veneer peeling is less than that by conventional lathes. In addition, the veneer production system incorporating the CI-VSL requires only one operator.

D.Veneer quality and veneer yield can be improved.