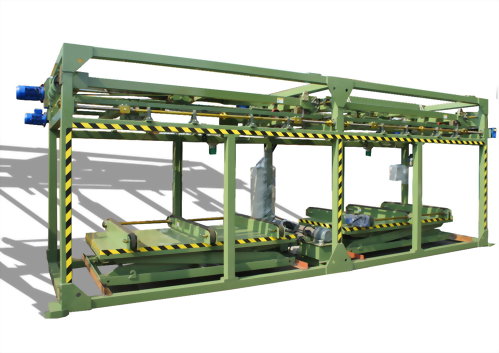

Automatic Board Thickness Measuring System

CI-TLM1400 Series

Automatic Board Thickness Measuring System

Product Overview

The CI-TLM1400 Series Automatic Board Thickness Measuring System is

specifically designed for high-precision, online, non-contact thickness

measurement of panel and board products.

By integrating advanced measuring technologies, it provides fast, accurate,

and reliable thickness measurement for various board materials, with

dependable data transmission capability—making it an ideal solution for modern

panel production lines.

Key Features & Advantages

• High-precision measurement: Delivers excellent accuracy to meet

stringent quality control requirements.

• Non-contact / contact options: Measurement method can be selected

according to board material and operating conditions.

• Online measurement: Enables real-time, continuous thickness monitoring

directly on the production line.

• No surface damage: Non-contact sensors are especially suitable for

fragile or soft materials.

• Multi-point measurement: Supports single-point, multi-point scanning,

or multiple sensor heads for comprehensive thickness profiling.

• Wide application range: Suitable for ambient, hot-rolling, and soft

material applications.

• Data integration: Multiple interfaces available for easy integration

with higher-level process control systems.

Measuring Principle & Configuration

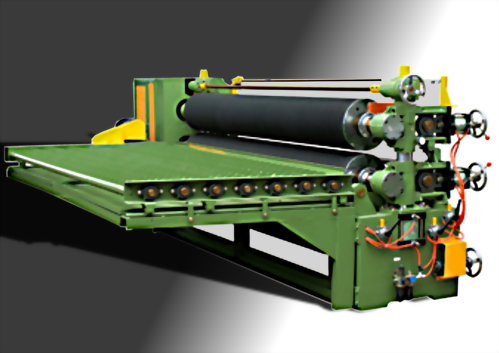

1. Non-Contact Laser Measurement

• Principle: Upper and lower opposing non-contact laser

displacement sensors are installed on the machine frame to measure board

thickness.

• Function: Supports single-point or multi-point scanning measurements,

or multiple sensor head installations to meet thickness inspection requirements

across wide panels.

• Advantages:

Non-contact measurement prevents surface damage and is suitable for various

production environments.

With optional cooling and dust-protection devices, the system can be applied to hot-rolled materials and soft boards that are difficult to measure using

conventional methods.

Data Transmission Interfaces

• System integration: Supports multiple interfaces, including Ethernet with TCP/IP, allowing measurement data to be transmitted to higher-level process control systems.

Applicable Board Types (Application References)

This system is suitable for thickness measurement of a wide range of rigid and flexible boards, including but not limited to:

• Wood-based panels:

Particleboard, Fibreboard, OSB, Plywood, HDF, Hardboard

• Building materials:

Gypsum board, Mineral fibre, Wood cement

• Solid wood & surface materials:

Solid wood, Veneer

• Plastics & rubber:

Plexiglass, Rubber

• Others:

(Customized upon request)

⚙️ Technical Specifications

|

Item |

Specification |

|

Power Supply Voltage |

230 V / 115 V |

|

Frequency |

50 Hz / 60 Hz |

|

Power Consumption |

750 VA |

|

Compressed Air Supply |

6 kg/cm² |

|

Compressed Air Consumption |

Approx. 3.5 L (per measurement, based on 5 sensor heads) |

|

Max. Number of Sensor Heads per Electronic Evaluation Unit |

20 (10 pairs) |

Measuring Accuracies

|

Measurement Type |

Specification |

Remarks |

|

Laser Measurement (70 mm measuring range) |

±0.1 mm |

Accuracy depends on measuring distance |