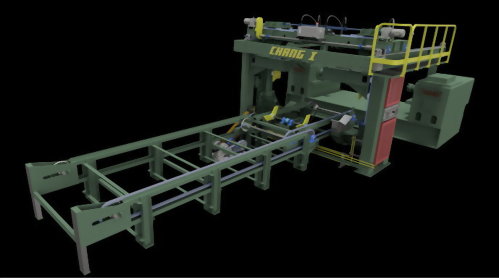

Veneer Composer (Veneer Core Builder)

The one operator working plc-type full veneer composer (veneer core builder) is specialized in cutting and jointing the monoplane veneer form 0.9mm to 4.5mm and simple operating by one worker, which from infeed conveyor, electronic veneer thickness detector, cutting, jointing by hot melt glue to desired length 4'×8' or 3'×6' and loading to automatic stacker, that all processes are operating by one perfect veneer composer (Veneer Core Builder).

In this machine, the core veneer is jointed and controlled by electronic detector, it has precise and solid joint spot, to prevent cracked after drying.

it is equipped with hot melt glue yarn for supplementary joint before the veneer is available for cutting,

Conveying speed of the machine is adjustable from 22m / min. to 33m / min. that will increase the production larger than the traditional the edge

Clipping and waste veneer counting are controlled by the precision rotary encoder and high-speed counter in order to clip the least waste veneer without any waste of core veneer. the minimum clipping width is 75mm.

Operation system is controlled by the PLC system, which is much easier to operate. the front and rear jointing are synchronized that makes the veneer jointed very precisely in order to prevent overlapping

Using 06/units of AC servomotor replace clutch brake drive can be more precision composing veneer edge for jointing perfectly. Driven Motor transmission by direct connection, Improve chain broke connection or Caused the loose.

New synchronous device system design, Distinctive pneumatic pressure following actuate synchronous jointing veneer, Good performance to composing wavy veneer and available working minimum thickness to 0.9mm and without overlap

VIDEO:

|

MODEL |

CI-VCB4-IVSS |

CI-VCB5-IVSS |

CI-VCB6-IVSS |

|

|

Length of Knife |

1350 mm |

1650 mm |

1950 mm |

|

|

Working Length |

968 mm to 1270mm |

1220mm to 1620mm |

1650mm to 1,850mm |

|

|

Working Thickness |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

|

|

Feeding Speed |

33m-36m/min |

28mm-33m/min |

24m-28m/min |

|

|

No. of glue threads |

5 |

6 |

7 |

|

|

No. of Edge-gluing (Points) |

20 |

26 |

28 |

|

|

No. of detectors |

20 |

22 |

28 |

|

|

No. of over thickness detectors |

2 |

2 |

2 |

|

|

MOTOR |

AC Servomotor System (Details specifications offered by quotation) |

|||

|

Optional Accessories: Air compressor with 3.7kw motor

(required 6kg/cm air pressure. 1200 liters’/min. free air

|

||||

|

MODEL |

CI-VCB7-IVSS |

CI-VCB8-IVSS |

CI-VCB9-IVSS |

|

|

Length of Knife |

2240 mm |

2750 mm |

2750 mm |

|

|

Working Length |

1650mm to 2100mm |

2000mm to 2600mm |

2400mm to 2700mm |

|

|

Working Thickness |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

|

|

Feeding Speed |

24m-28m/min |

22m-26m/min |

22m-26m/min |

|

|

No. of glue threads |

8 |

9 |

10 |

|

|

No. of Edge-gluing (Points) |

30 |

36 |

40 |

|

|

No. of detectors |

34 |

40 |

40 |

|

|

No. of over thickness detectors |

2 |

2 |

2 |

|

|

MOTOR |

AC Servomotor System (Details specifications offered by quotation) |

|||

|

Optional Accessories: Air compressor with

3.7kw motor

(required 6kg/cm air pressure. 1200 liters’/min. free air

|

||||

Customized Design Type

-Turner Device Stacker + Timesavers-

Customized Design Type

-Safety Light Curtain with Fence + Operating Platform + Size Cutting Auto Adjustable Device Controller

Customized Design Type

-AF System (Veneer Sheet Auto Feeder)-