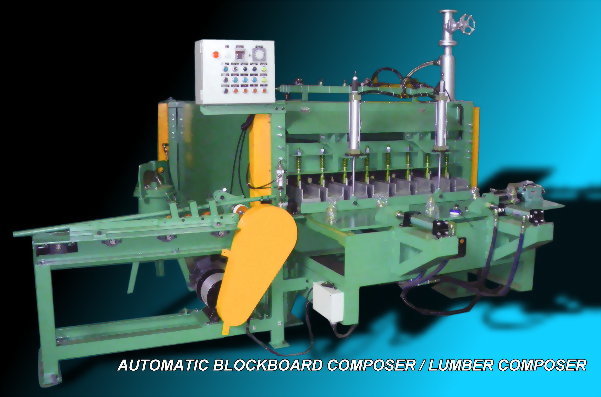

Semi-Automatic Block Board Composer

8’半自動木芯拼板機主要針對人工費用低廉地區需要大量生產之木材加工業所設計。有別於敝公司另兩項產生;8’與16’全自動木芯拼板機。

為了機械於操作中的穩定性及容易安裝機械,在此設備之底部加裝一整片之鋼板。

將預先排列整齊塗妥膠水足夠拼成一片板之木條整批插入餵料槽中,木條由空壓系統下壓再經油壓推送桿推入加熱區中加熱。

餵料之推送速度是可調整的。最大推送速度可達到每分鐘45次。

成品之長度可定位於6’、7’、8’。由圓片鋸切除木條長度超出之部份。切除之短木料亦可回收使用!

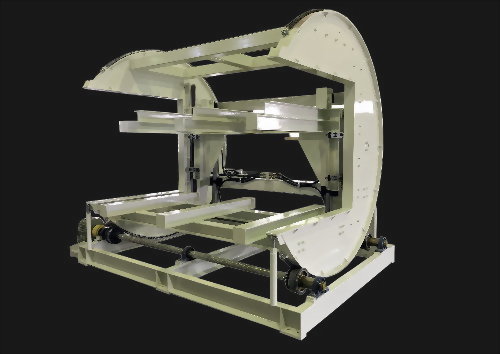

上下層蒸氣加熱管組鋼板不但加厚而且經熱處理後再刨平,經長期使用後亦不會變形。特別加寬之蒸氣加熱管面可使生產流程順暢穩定。

由4組獨立油壓柱調整上蒸氣加熱管組之升降。依據成品厚度分別調整油壓柱高低以定位上下蒸氣加熱管組間適當間隙。

每支蒸氣加熱管背部均裝設彈簧可確保蒸氣加熱管與木條間最佳之接觸

Block Board Composer Model:CI-BC8-SA is specialized in producing various sizes of lumber/block core board thickness.

AB-8 equips with wide face and bottom heater 17 pieces for each, and the steam or oil as media to supply heat for heaters to pressing and composing the strips.

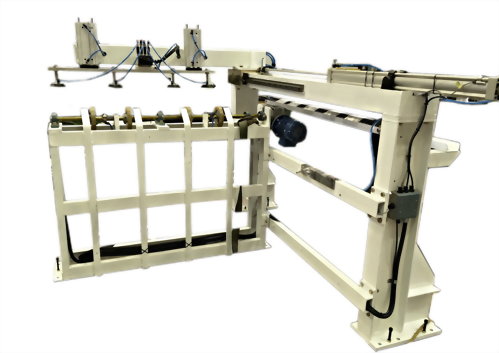

Automatic glue applicator applies the glue to the feeing strips and the feeder delivers them into composing section.

The strips are fed by the auto feeder one after another till fixed width, the circular saw cuts it off automatically. Afterward the full width strip is pushed into the heater by the hydraulic and Air pressure device for composing.

Heater:

The upper heaters are able to lift individually and it can be adjusted for the clearance between upper and lower heaters. Meanwhile, according to the strips thickness, the gap can be adjusted to fit for the production.

Each upper heater equipped with springs which always ensure the heater is always in the best contact / connection with the strips.

Model:CI-BC8-SA

|

Item |

|

|

Length of Product |

1,880~2,514mm (6’,7’,8,) |

|

Strip Thickness |

8~25mm |

|

Strip Width |

35~50mm |

|

Motor for Oil Pump |

10HP×4P |

|

Motor for Circular Saw |

5HP×2P |

|

Power |

11.25 KW |

|

Steam Pressure |

3~7 kgs/cm2 |

|

Compressed Air |

5 kgs/cm2 |

|

Max.Pushing Speed |

45 strokes/min |

|

Hydraulic Control System |

1 set |

|

Pneumatic Control System |

1 set |

|

Electric Control System |

1 set |

|

Upper Steam Headers |

130×130×4,000mm×17pcs |

|

Lower Steam Headers |

130×130×3,715mm×17pcs |

|

Consumption |

70 kgs/hr |

|

Machine Size |

5,420×3,260×2,050mm |

|

Net Weight |

Approx 7,000 kgs |

|

Gross Weight |

Approx 7,500 kgs |